Industrial dispersion and agitation equipment for processing paints, coatings, EV battery slurries, and other chemical products

Admix industrial mixing equipment is installed at chemical manufacturing plants around the world. Our batch and inline dispersion mixers are available with industrial painted motors, in both Class 1 Div. 1, and Class 1 Div. 2 explosion proof motors.

Admix industrial mixing equipment is installed at chemical manufacturing plants around the world. Our batch and inline dispersion mixers are available with industrial painted motors, in both Class 1 Div. 1, and Class 1 Div. 2 explosion proof motors.

Our industrial mixers employ high intensity (shear) mixing to disperse ceramics, deagglomerate powders into liquids, and eliminate fisheyes for more uniform pre-mixes and end products. Admix has success across numerous applications including the emulsion and dispersion of pigments, additives, polymers, plastics, adhesives, resins, polyols, and many other materials – see the bottom of this page for a list of applications.

Download the datasheet: Chemical Process Overview

Highly Efficient Dispersers

Our advanced mixing technologies enable chemical manufacturers to improve the quality of their mixed material. Your pre-mixes will be agglomerate-free, minimizing your mill’s maintenance costs and reducing media mill screen clogging.

Our advanced mixing technologies enable chemical manufacturers to improve the quality of their mixed material. Your pre-mixes will be agglomerate-free, minimizing your mill’s maintenance costs and reducing media mill screen clogging.

- Reduce batch times

- Reduce maintenance costs

- Reduce clogged media mill screens

- Eliminate air entrainment

- Quickly eliminate agglomerates with our Rotosolver high shear mixing head

Dispersion Equipment for Chemical Processing

Dynashear CX inline mixer – Available with camlock or NPT fittings, the Dynashear is an inline dual stage disperser / emulsifier for inline continuous processing or batch processing with recirculation. It will instantly blend, dissolve, deagglomerate, disperse, and emulsify a wide range of fluids and semi-fluids. The Dynashear can be connected to the outlet of your mix tank to instantly emulsify the mixture. This is useful if your batch mixer does not have enough shear to complete mixing in a reasonable amount of time.

Dynashear CX inline mixer – Available with camlock or NPT fittings, the Dynashear is an inline dual stage disperser / emulsifier for inline continuous processing or batch processing with recirculation. It will instantly blend, dissolve, deagglomerate, disperse, and emulsify a wide range of fluids and semi-fluids. The Dynashear can be connected to the outlet of your mix tank to instantly emulsify the mixture. This is useful if your batch mixer does not have enough shear to complete mixing in a reasonable amount of time.

It is designed to provide maximum versatility to meet your chemical processing needs. Whether you’re looking for a stand-alone inline mixer, a mixer to augment your batch process agitator, or further product refinement, the Dynashear ensures consistent quality with precise reproducibility.

The Dynashear enables you to refine your pre-mix so that there’s less wear on your mills from undispersed material. Designed for 24/7 operation, it offers flow rates up to 175 GPM and seal pressure ratings up to 450 PSI at 400° F. See how it works.

Fastfeed powder induction and dispersion system – when you need instant 100% dispersion of your powder ingredients, look no further than the Admix Fastfeed. This powerful powder induction and dispersion system features our proven high shear mixing technology and an ergonomic design. Its skid-mounted, inline system vacuums and conveys up to 500 pounds per minute depending on the powder, from the safety of floor level. It wets out, hydrates, and disperses powders in a single pass in most cases, instantly creating a 100% completely homogeneous mixture free of lumps, agglomerates and fisheyes. See the latest Fastfeed video to learn how it can help your process.

Fastfeed powder induction and dispersion system – when you need instant 100% dispersion of your powder ingredients, look no further than the Admix Fastfeed. This powerful powder induction and dispersion system features our proven high shear mixing technology and an ergonomic design. Its skid-mounted, inline system vacuums and conveys up to 500 pounds per minute depending on the powder, from the safety of floor level. It wets out, hydrates, and disperses powders in a single pass in most cases, instantly creating a 100% completely homogeneous mixture free of lumps, agglomerates and fisheyes. See the latest Fastfeed video to learn how it can help your process.

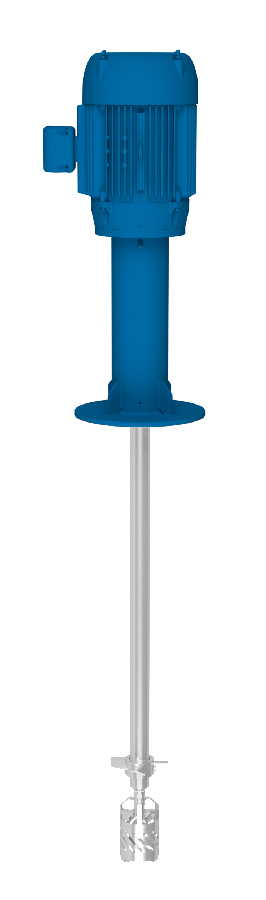

The Rotosolver high shear mixer is our flagship product with thousands of installations for chemical high shear mixing and blending around the world. For in-tank processes requiring 100% wetting out of powders, the Rotosolver’s patented design provides higher overall shear rates, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons.

The Rotosolver high shear mixer is our flagship product with thousands of installations for chemical high shear mixing and blending around the world. For in-tank processes requiring 100% wetting out of powders, the Rotosolver’s patented design provides higher overall shear rates, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons.

The Rotosolver outperforms competitors in key performance areas. It is designed to efficiently apply every bit of energy to produce either mechanical or hydraulic shear and optimally direct flow that is beneficial to the process.

For various applications, compared to traditional saw tooth blades, the Rotosolver delivers:

- up to 30% less energy consumption

- 3X the pumping capacity compared to traditional sawtooth discs

- equivalent or greater shear rate with up to 20% less tip speed requirement

- dual functionality as high shear disperser or rapid blending station with up to 6X more throughput (for example, customers can create concentrates requiring high shear and generate finished product requiring rapid blending in the same vessel)

Try the Rotosolver high shear industrial mixer at your Plant – trial skid includes mixer, tank, and VFD controller. A two-week trial gives you the opportunity to try the Rotosolver using your own materials and with your own operators / R&D team running the equipment. Download the flyer to learn more: Rotosolver Mixer Trial Skid

The BSM disperser / homogenizer outperforms conventional shear pumps and colloid mills and provides very high throughputs at extreme shear rates. This heavy duty inline rotor/stator machine delivers 24/7 operation; rapidly wets out powders to primary particle size and with more friable powders even reduces aggregate size; and withstands uneven flow patterns, jolts, and pressure fluctuations.

The BSM disperser / homogenizer outperforms conventional shear pumps and colloid mills and provides very high throughputs at extreme shear rates. This heavy duty inline rotor/stator machine delivers 24/7 operation; rapidly wets out powders to primary particle size and with more friable powders even reduces aggregate size; and withstands uneven flow patterns, jolts, and pressure fluctuations.

For milling of soft particles to <1 micron, or hard particles down to 1-2 microns, the BSM produces superior particle size reduction, often in a single pass at high production rates. Choose from over 20 variations from course to ultra-fine.

Diaf Dispersion Equipment

In 2022, Admix acquired Diaf Pilvad including all of their equipment lines. For over 100 years, the Diaf brand has been associated with providing extremely robust and efficient mixing and dispersing equipment to premiere manufacturers of paints, coatings, varnish, and printing inks.

In 2022, Admix acquired Diaf Pilvad including all of their equipment lines. For over 100 years, the Diaf brand has been associated with providing extremely robust and efficient mixing and dispersing equipment to premiere manufacturers of paints, coatings, varnish, and printing inks.

Diaf Dissolver CX: High speed and high shear dispersers for pre-mixing, dispersion, and finishing batches. These high performance units are available in benchtop small production and R&D scale to full scale high volume production sizes (5 – 1500 gallon mixing capacity. They are equipped with a sawtooth disc blade and can be equipped with our patented Rotosolver high shear mix head for maximum shear and pumping rates. Download Diaf Dissolver CX brochure.

Diamix CX: Enclosed system designed for dispersion and dissolving. The Diamix will disperse, dissolve, and homogenize both high and low viscosities, in addition to thixotropic liquids. The system consists of a Diaf Dissolver and an anchor agitator with spring loaded scrapers and an optional screw conveyor. Download Diamix CX brochure.

Diamix CX: Enclosed system designed for dispersion and dissolving. The Diamix will disperse, dissolve, and homogenize both high and low viscosities, in addition to thixotropic liquids. The system consists of a Diaf Dissolver and an anchor agitator with spring loaded scrapers and an optional screw conveyor. Download Diamix CX brochure.

Applications for Admix chemical mixing and blending equipment

Emulsions: Admix mixers produce emulsions with small, uniform droplet size. These emulsions lead to increased shelf-life, stability and quality without the use of a high-pressure homogenizer.

- Wax emulsions

- Paper sizing emulsions

- Coatings and paints

- Catalyst slurries

- Lubricant slurries

- EV battery materials slurries

- Sealants (e.g., wood products)

- Polymer and polymerization precursors

- Anti-foam emulsions

- Monomer emulsions

- Incorporation of low-HLB surfactants into aqueous systems

Dispersions and Mixing: Admix mixers and dispersers employ high shear and high intensity mixing to disperse ceramics, deagglomerate powders into primary particles, and eliminate fisheyes in hydrocolloids and thickeners. Our high shear equipment produces more uniform end products much more quickly and efficiently than conventional dispersers.

- Biofuels

- Coatings (Automotive, Industrial, Architectural, etc.)

- Drilling Muds

- Agrochemicals, Crop protection and fertilization products

- Car polishes and polishing compounds

- Dispersion of powders

- Clay dispersions

- Inks

- Adhesives

- Polymers

- Elastomers

- Disperse iron oxides for magnetic media

- Metal oxides

- Dispersions for capacitors

- Dispersions of ceramics

- Produce CMP (chemical mechanical polishing) compounds

- Pulp and paper applications

- Paints & Pigments, organic and inorganic

- Gel formation for batteries or battery paste

- Disperse and hydrate Carbopol, Rhodopol, Natrisol, and other viscosity-modifying ingredients

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer