Pigment Mixing | Industrial Mixers for Pigments

Pigments are indispensable to every industry. Mixers for pigments must address two requirements: dispersion and particle size reduction. Finding commercial pigment mixing equipment that disperses efficiently and eliminates agglomerates, and can reduce particle size down to 1-5 micron or less is critical for success.

Pigments are indispensable to every industry. Mixers for pigments must address two requirements: dispersion and particle size reduction. Finding commercial pigment mixing equipment that disperses efficiently and eliminates agglomerates, and can reduce particle size down to 1-5 micron or less is critical for success.

Pigments can be inorganic like metallic oxides, metal powder suspensions, and carbon black, or organic such as animal melanin, vegetable carotene, lake pigments, and toners. Admix has extensive experience with titanium dioxide, lake pigments, inks, dyes, and some iron oxides.

Featured Products

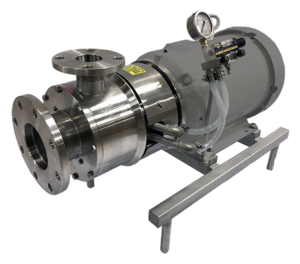

Particle size reduction occurs with a high shear mixer running in a batch operation (such as the Rotosolver), or in a continuous inline operation using the Boston Shearmill. Combining batch mixing with recirculation through an inline device offers the optimal setup.

Particle size reduction occurs with a high shear mixer running in a batch operation (such as the Rotosolver), or in a continuous inline operation using the Boston Shearmill. Combining batch mixing with recirculation through an inline device offers the optimal setup.

Pre-mixing ensures that all surfaces are wetted out and agglomerates are broken down. Plus, a good pre-mix drastically reduces the burden put on shearmills downstream to achieve the final particle size. The refractory properties of the materials and the hardness of the particles determine the equipment needed and whether it can be done in one step, but often it’s possible to perform both pre-mixing and final milling in one operation.

When pigments are used for making an emulsion of soft to semi-hard particles, either the Dynashear inline disperser or the Rotosolver can be used in a batch mode. Both pigment mixing machines deliver particle size in the 2-4 micron range. Most pigments can be completely processed with our Boston Shearmill configured in a recirculation mode where multiple passes over 10-30 minutes will achieve results down to 1 micron or less.

When pigments are used for making an emulsion of soft to semi-hard particles, either the Dynashear inline disperser or the Rotosolver can be used in a batch mode. Both pigment mixing machines deliver particle size in the 2-4 micron range. Most pigments can be completely processed with our Boston Shearmill configured in a recirculation mode where multiple passes over 10-30 minutes will achieve results down to 1 micron or less.

Many hard particle pigments can be premixed and milled to particles in the 4-10 micron range in a batch reactor alone using our Rotosolver or Rotostat set at a high tip speed, eliminating the need for further downstream refinement. Admix recommends lab testing for optimal pigment mixing results. Running both benchtop and 10-100 gallon pilot tests will ensure scale-up success for larger batches or continuous runs.

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer