High Shear and Flow for Efficient Dispersion

Compared to conventional dispersion prior to media milling, the high shear Rotosolver will improve your process! The Rotosolver in-tank disperser is engineered for wetting out of powders and eliminating agglomerates in just minutes. The results are reduced energy consumption, batch times, maintenance on your media mills, and media mill screen clogging.

How the Rotosolver Works:

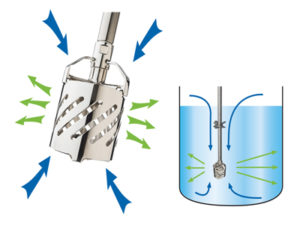

The Rotosolver combines the shearing capabilities of a high speed toothed rotor and a slotted stator with the additional advantage of high flow / circulation from the dual rotor blades. This unique mixing head design of the disperser provides a four-stage mixing action:

The Rotosolver combines the shearing capabilities of a high speed toothed rotor and a slotted stator with the additional advantage of high flow / circulation from the dual rotor blades. This unique mixing head design of the disperser provides a four-stage mixing action:

- Product flow is drawn into the mixing head from above and below. As flow is drawn in, materials are pulled down from the top and immediately exposed to two additional mechanical shear zones and one shear zone from the bottom. These materials are then immediately mechanically ripped by the teeth on the rotor’s discharge at the top and bottom of the stator.

- Two high velocity, countercurrent streams converge within the stator causing high turbulence and hydraulic shear, without momentum loss from obstructions within the stator.

- Centrifugal pressure forces material to the periphery of the stator where it is subjected to further mechanical shear from the sharpened edges of the expanded slots in the stator.

- The high velocity radial discharge combines with slower moving tank flow for additional hydraulic shear and circulation.

Try the Rotosolver® High Shear Industrial Mixer at your Plant

The Admix Rotosolver is the industry’s leading high shear batch mixer for quickly and effectively wetting out and dispersing powders for chemical processors.

2-Week Rotosolver Trial for your Chemical Mixing Applications

A Trial gives you the opportunity to try the Rotosolver using your own materials and with your own operators / R&D team running the equipment. During the Trial, we encourage you to compare it to your current mixer, noting how the Rotosolver performs in terms of overall mixing time, flow, energy reliance, and efficiency with your current processes. We are confident you’ll find that it outperforms in critical categories and provides:

- An optimal balance between shear and flow

- Excellent product flow patterns and turnover in the tank

- Greatly reduced mixing times

- Lower heat input

- Lower power consumption

- Superior mixing and dispersing

- 100% dissolving, hydrating, and suspension

- Single shaft, obstruction-free design

- One piece, clean-in-place (CIP) mixing head

- All stainless mixing head, shaft, drive, and motor available

- Optional secondary foils

- 100% scalability

Everything You Need to Start Your Trial

The Rotosolver trial mixer is fully enclosed on a “Skid” with removable front panels for easy access to the mixer, tank, and electrical panel, etc. Fork-lift pockets are mounted at the bottom of the skid for transporting it around your plant. The skid contains:

- Rotosolver high shear mixer, model 132RS88-SS, 15HP explosion proof motor

- 100-gallon stainless steel tank (not jacketed) with a bottom discharge valve

- Industrial VFD Controller, Class 1 Division 1, enclosure ready to be wired to your electrical source

- Analog AMP and Hz Readouts

- Operating Instructions and Equipment Manual

Standard trial periods are 14-days from receipt to return shipment. Unit should be fully cleaned and assembled prior to returning. We will provide you with return labels.

Admix Support

Our Sales Engineers, Chemical Market Manager, and Manufacturer Representatives, will be available to assist you with your Rotosolver Trial.

Contact Us

*Required field

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer