The Beverage Industry

Revolutionize Your Beverage Production with Admix

In today’s dynamic market, the surge in popularity of sports drinks, nutraceuticals, and other health-focused beverages has made traditional mixing technology obsolete. These beverages demand innovative solutions to be produced efficiently and economically.Enter Admix. For decades, our state-of-the-art sanitary mixers have been at the forefront of beverage processing, consistently evolving to meet the needs of new formulas and applications. Our commitment to innovation ensures that you can produce high-quality beverages with ease. As the beverage industry continues to grow and diversify, Admix partners with manufacturers to create a wide array of beverage types, ensuring you stay ahead of the curve.

Mixing/Processing Problems Solved

- Slow batch times- Lumps, clumps, or fisheyes

- Clogged strainers

- Inconsistent powder incorporation

- Batch-to-batch inconsistencies

- Inefficiencies dispersing more powder into less water

- Dusting

- Air entrainment

- Operator injuries/safety considerations

Dynashear inline mixer

This system’s 3-A compliant design enables you to prevent premature plate heat exchanger burn-on, clogged strainers, and mid-day flushouts or mini-CIPs resulting from undispersed ingredients and stabilizers. Designed for 24/7 operation, it offers flow rates up to 175 GPM and seal pressure ratings up to 450 PSI at 400° F. Install the Admix Dynashear® two-stage high speed disperser immediately upstream of the HTST balance tank to guarantee no agglomerates or fisheyes.

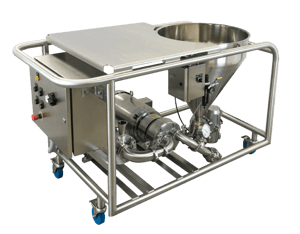

Fastfeed powder induction system

If you need 100% dispersion of proteins, gums, starches, vitamins, fiber, sweeteners, stabilizers, emulsifiers, flavors, and colors, look no further than the Fastfeed. This system instantly wets, disperses, and hydrates these popular ingredients in a single pass with no clumps or foam as it is filling your batch tank. Plus you get controlled feed rates up to 450 pounds per minute from the safety of floor level.

Boston Shearmill wet mill/homogenizer

The 3-A compliant Boston Shearmill wet mill/homogenizer outperforms conventional shear pumps and colloid mills and provides very high throughputs at extreme shear rates. Inline rotor-stator machines deliver 24/7 operation; reduce solids particles with minimal dust formation; and withstand uneven flow patterns, jolts, and pressure fluctuations. And for milling of soft particles to <1 micron, or hard particles down to 1-2 microns, the shearmill produces superior particle size reduction, often in a single pass at high production rates.

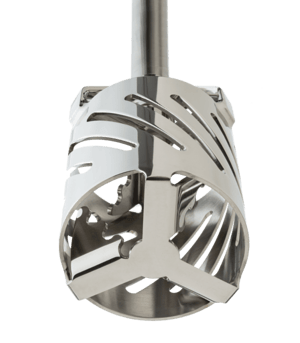

Rotosolver high shear mixer

This is our flagship product with thousands of installations at food and beverage processing plants around the world. For production lines requiring 100% wetting out of powders, the Rotosolver’s patented 3-A compliant design is easy-to-clean and provides higher overall shear rates, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons.

The Rotosolver outperforms competitors in key performance areas. For various applications, it has delivered up to:

- 50% less energy consumption

- 600% higher flow rates

- 20% higher tip speeds

- 6 times more throughput than conventional mixers