The Cosmetics & Personal Care Industry

INNOVATIVE SOLUTIONS IN PERSONAL CARE & COSMETICS MIXING TECHNOLOGIES

Crafting secure and dependable products for skincare, haircare, and overall body wellness, Admix stands at the forefront, providing cosmetic and personal care manufacturers with a comprehensive array of advanced mixing solutions. Whether your product line requires the subtle integration of scents and hues or the development of ultra-fine emulsions for luxurious creams and lotions, Admix brings to the table not only top-tier equipment but also a wealth of expertise to ensure your creations meet the highest standards of excellence.

Mixing/Processing Problems Solved

- Slow batch times- Lumps, clumps, or fisheyes

- Clogged strainers

- Inconsistent powder incorporation

- Batch-to-batch inconsistencies

- Inefficiencies dispersing more powder into less water

- Dusting

- Air entrainment

- Operator injuries/safety considerations

Rotosolver high shear mixer

If your production line requires 100% wetting out of powders, and an easy-to-clean design that meets 3-A sanitary requirements, the Rotosolver® is the solution. The Rotosolver design includes two additional shear zones providing higher overall shear rates, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons (37,854 liters).

The Rotosolver powder-liquid disperser offers key benefits including:

- High-intensity optimum shear

- One-piece clean-in-place (CIP/SIP) mix head

- 3-A Certified

- Single shaft, obstruction-free design

- All stainless mix head, shaft, drive and motor available

- Optional secondary impellers

- 100% dissolving, hydrating or suspension

- Lab models and production sizes up to 100 HP

Benchmix series of lab mixers

The Benchmix® series of lab mixers offers sanitary, all stainless steel benchtop laboratory mixers designed for product development, simulation, and scale up for batches up to 5 gallons (20 liters).

For small production runs up to 20 gallons (75 liters), the Rotosolver RS-02 pilot plant floor model is also available. See how Admix offers these predictable, repeatable results all the way up to 10,000 gallons with a process assurance warranty on both Benchmix process results as well as through our free lab testing service.

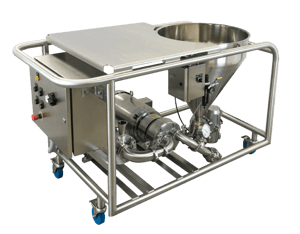

Fastfeed powder induction system

Discover the revolution in ingredient processing with the Fastfeed® powder induction and dispersion system. This cutting-edge system effortlessly integrates, moistens, and disperses a variety of ingredients, completely eradicating any lumps. Whether it's proteins, gums, starches, vitamins, fiber, sweeteners, stabilizers, emulsifiers, flavors, or colors, our system handles them with unparalleled efficiency, dispersing up to 450 pounds (204 kilograms) per minute seamlessly in a single pass. Not only does it outperform traditional tank mixers by consuming up to 70% less energy, but it also guarantees consistency batch after batch by introducing powders at a consistent rate every time. Further enhancing its value, the Fastfeed system significantly reduces batch times and minimizes air entrainment, offering a smooth, streamlined process. Additionally, it addresses workplace safety and cleanliness by eliminating the dust associated with dumping powders into open tanks and enhances operator safety by allowing powders to be added from the safety of floor level.

Dynashear inline high speed emulsifier

The Dynashear® inline high speed emulsifier disperses gums, stabilizers, proteins and sweeteners in a single pass delivering batch times as low as 3-5 minutes and less air entrainment. With flow rates up to 175 GPM, the 3-A compliant Dynashear delivers smooth product every time with no fisheyes or agglomerates. The two-stage rotor/stator action allows processors to run longer and CIP less frequently. When installed upstream of inline strainers or HTST balance tanks, the Dynashear improves your process, preventing clogged strainers and extending the life of pumps, valves, and seals.

FEATURED VIDEO

Dispersing carbomer.