The Dressings & Sauces Industry

ENHANCING MIXING EQUIPMENT FOR THE DRESSINGS & SAUCES INDUSTRY

In recent times, the landscape of the salad dressing, mayonnaise, and sauce industry has undergone a significant transformation. A surge in demand for ethnic, organic, reduced-calorie, and international options has captured the hearts of consumers, particularly driven by food service professionals and the millennial generation's pursuit of products bearing the "clean label" seal. This shift has not only redefined consumer preferences but also introduced complex challenges for processors in search of high-caliber commercial mixing solutions. As the industry evolves, our commitment to innovation, reliability, and support ensures we remain at the forefront, ready to tackle the intricacies of new ingredients and meet the ever-growing demands with unparalleled mixing equipment.

Mixing/Processing Problems Solved

- Slow batch times- Lumps, clumps, or fisheyes

- Clogged strainers

- Inconsistent powder incorporation

- Batch-to-batch inconsistencies

- Inefficiencies dispersing more powder into less water

- Dusting

- Air entrainment

- Operator injuries/safety considerations

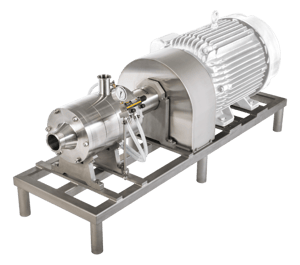

Admix Mayomill Inline Wet Mill

Admix takes immense pride in being an integral part of the Association of Dressings & Sauces, bringing forward innovative solutions specifically tailored for the salad dressing and mayonnaise manufacturing processes. At the heart of our product line is the Admix MayoMill, ingeniously developed from the highly acclaimed Boston Shearmill framework. This evolution means that common challenges such as the necessity for disassembly for thorough cleaning and the risks of seal damage due to high pressures are effectively addressed and resolved. Engineered for convenience, the MayoMill is designed to be Clean-In-Place (CIP), ensuring adherence to the stringent 3-A sanitary standards (#36-01), optimizing operational efficiency while maintaining the highest levels of hygiene and safety.

Rotosolver High Shear Mixer

If your production line requires 100% wetting out of powders, and an easy-to-clean design that meets 3-A sanitary requirements, the Rotosolver is the solution. The Rotosolver design includes two additional shear zones providing higher overall shear rates, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons (27,854 liters).The Rotosolver outperforms competitors in key performance areas. For various applications, it has delivered up to:

- 50% less energy consumption

- 600% higher flow rates

- 20% higher tip speeds

- 6 times more throughput than conventional mixers

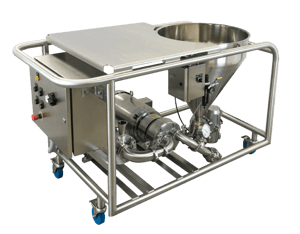

Fastfeed Powder Induction System

Discover the revolution in ingredient processing with the Fastfeed powder induction and dispersion system. This cutting-edge system effortlessly integrates, moistens, and disperses a variety of ingredients, completely eradicating any lumps. Whether it's proteins, gums, starches, vitamins, fiber, sweeteners, stabilizers, emulsifiers, flavors, or colors, our system handles them with unparalleled efficiency, dispersing up to 450 pounds (204 kilograms) per minute seamlessly in a single pass. Not only does it outperform traditional tank mixers by consuming up to 70% less energy, but it also guarantees consistency batch after batch by introducing powders at a consistent rate every time. Further enhancing its value, the Fastfeed system significantly reduces batch times and minimizes air entrainment, offering a smooth, streamlined process. Additionally, it addresses workplace safety and cleanliness by eliminating the dust associated with dumping powders into open tanks and enhances operator safety by allowing powders to be added from the safety of floor level.

Dynashear Inline High Speed Emulsifier

The Dynashear inline high speed emulsifier disperses gums, stabilizers, proteins and sweeteners in a single pass delivering batch times as low as 3-5 minutes and less air entrainment. With flow rates up to 175 GPM, the 3-A compliant Dynashear delivers smooth product every time with no fisheyes or agglomerates. The two-stage rotor/stator action allows processors to run longer and CIP less frequently. When installed upstream of inline strainers or HTST balance tanks, the Dynashear improves your process, preventing clogged strainers and extending the life of pumps, valves, and seals.