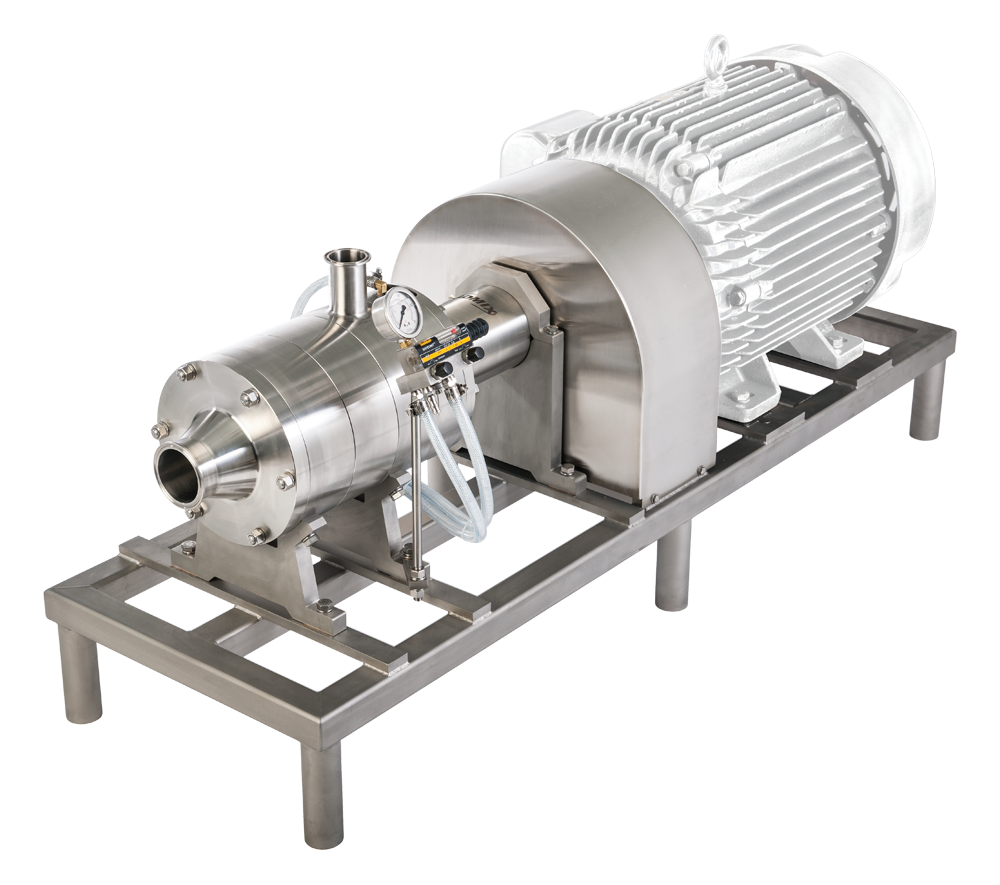

Admix Mayomill Inline Wet Mill

How it Works | Specifications | Options

The seasonings, sauces and condiments market in the US is estimated at over $22 billion in revenue and the US consumes over $2 billion in mayonnaise every year. Mayonnaise and salad dressing processing can be a challenge, however, with the emergence of new low fat and egg-free recipes.

The seasonings, sauces and condiments market in the US is estimated at over $22 billion in revenue and the US consumes over $2 billion in mayonnaise every year. Mayonnaise and salad dressing processing can be a challenge, however, with the emergence of new low fat and egg-free recipes.

Conventional mayonnaise, whipped salad dressings, and some creamy salad dressings must be milled after mixing to make emulsions uniform and shelf-stable. The Admix Mayomill is an inline milling device designed to eliminate the common issues with conventional, colloid mills popular throughout the industry.

Featured Video

Features/Benefits – Mayomill vs. colloid mills

Wet milling substances with rotor-stator machines provides several advantages. Designed to run 24/7, our wet mills mix, disperse, emulsify, pulverize, macerate, crush, homogenize, and reduce solids particles with minimal dust formation, and withstand uneven flow patterns, jolts and pressure fluctuations.

Here are a few of the Mayomill’s design features and benefits:

Cleanability

Conventional colloid mills are not CIP-able which forces manual cleaning. This increases total cost of ownership due to:

- Additional labor costs associated with cleaning

- Potential equipment damage during CIP

- Line start-up delays after cleaning due to improper reassembly and adjustment

- Wasted time and product while resetting the mills

The Mayomill is truly CIP and eliminates all manual cleaning which equates to a huge cost savings in repair parts (especially seals) and increased filler efficiency due to faster line start-ups.

Creates Stable Emulsions for Fragile Product

Mayonnaise is a very fragile emulsion. The egg yolk in a formula coats the oil droplets, and a textbook mayo emulsion has 3-5 micron oil droplets with a 99.999 distribution in that range.

Reducing the amount of egg in a formula can mean big cost savings, but as egg is reduced, the emulsion gets fragile. Customers note that the Mayomill has a “very wide sweet spot,” producing emulsions that are much more stable and less susceptible to breaking or separation.

Superior Mechanical Seals

Mayonnaise can reach viscosities of 300,000+ CPS and is often pumped great distances from the kitchen to the filler. Blown seals in conventional mills are common and costly, resulting in higher maintenance costs, more downtime, and loss in filler efficiency.

While typical seals in colloid mills max out at 300 PSI or less, the Admix Mayomill’s seals are rated for a 725 PSI, eliminating seal failures caused by over pressurization.

Product Cost Reduction

With the ever-increasing cost of soybean oil (~80% of what mayo is made from) along with the volatility of egg supply and prices (~4% of what mayo is made from), many manufacturers want to reduce oil and egg costs. Typically, this cannot be done effectively with conventional colloid mills.

The Mayomill shear is optimum for both conventional and low cost formulas allowing manufacturers great flexibility for cost reductions within their formulas.

Shear Rate Adjustments

Mayonnaise requires a very specific shear, which is adjusted on conventional colloid mills by changing the gap. This is done by dialing an external ring mechanism that is not always accurate or repeatable. Tightening the gap also causes increased and fluctuating back pressure which leads to added stress on seals and texture changes in the mayonnaise. Many times during a run, the shear rate needs to be adjusted for minor changes like egg temperature fluctuation.

The Admix Mayomill needs no gap adjustment. The gaps in the 9 individual points in the Mayomill are fixed and have been optimized to create the right shear for mayonnaise, dressings, and other products. Shear rate adjustments are simply made by adjusting RPM electronically through the speed control. Basic settings are provided for each product family and then simple tweaks to hertz (Hz) are made as each formula is run the first time, and a final Hz level then set and used going forward.

Increased Throughput

Current colloid mill designs have limited throughput, forcing manufacturers to install multiple mills in parallel for higher throughput. Use of multiple mills may adversely cause:

- Inconsistent product between the different mills reaching the filler

- Additional cleaning issues

- Higher overall total cost of ownership

- Product to become fragile due to increased BP

- Seal issues

A single Admix Mayomill delivers throughput up to 110 GPM.

How can the Mayomill improve your process?

Get a customized quote or inquire about free lab testing today!

Download Datasheet

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer