Cosmetics & Personal Care Industry

To create safe, trusted consumer products for the face, hair and body, cosmetics and personal care producers utilize a wide range of mixing technologies from Admix. Whether you need simple color or fragrance blending or need to create extremely fine emulsions in creams and lotions, Admix has the high quality equipment and experience to help you deliver.

Want to see our equipment in action or take it for a test drive? Our comprehensive mixing equipment services can improve your process and bottom line today.

- Get a customized quote

- Schedule free formula testing in our lab

- Request free passes to trade shows we’re attending

- Learn about our trial program incentives or request an onsite demo

- Get guaranteed scale-up with a process assurance warranty to ensure your product is to made to spec and goes to market faster

Cosmetic Processing Equipment and Services

Dynashear inline mixer – this system’s 3-A compliant design enables you to prevent premature plate heat exchanger burn-on, clogged strainers, and mid-day flushouts or mini-CIPs resulting from undispersed ingredients and stabilizers. Designed for 24/7 operation, it offers flow rates up to 175 GPM and seal pressure ratings up to 450 PSI at 400° F.

Dynashear inline mixer – this system’s 3-A compliant design enables you to prevent premature plate heat exchanger burn-on, clogged strainers, and mid-day flushouts or mini-CIPs resulting from undispersed ingredients and stabilizers. Designed for 24/7 operation, it offers flow rates up to 175 GPM and seal pressure ratings up to 450 PSI at 400° F.

Install the Admix Dynashear two-stage high speed disperser immediately upstream of the HTST balance tank to guarantee no agglomerates or fisheyes.

Learn more about the Dynashear.

Rotosolver high shear in-tank mixer: The Rotosolver is our flagship product for fast, 100% dispersion of Carbomers. The Rotosolver’s patented 3-A compliant design is easy-to-clean and provides higher overall shear rates, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons. The Rotosolver outperforms competitors in key performance areas.

Rotosolver high shear in-tank mixer: The Rotosolver is our flagship product for fast, 100% dispersion of Carbomers. The Rotosolver’s patented 3-A compliant design is easy-to-clean and provides higher overall shear rates, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons. The Rotosolver outperforms competitors in key performance areas.

For various applications, it has delivered up to:

- 50% less energy consumption

- 600% higher flow rates

- 20% higher tip speeds

- 6 times more throughput than conventional mixers

Learn more about the Rotosolver in-tank high shear mixer.

The Benchmix is a benchtop lab mixer specifically designed for product development, simulation and scale up. The Benchmix provides predictable, repeatable results from the development lab to full production when scaling up to an Admix high shear production size mixer – we back this with our process assurance warranty!

The Benchmix is a benchtop lab mixer specifically designed for product development, simulation and scale up. The Benchmix provides predictable, repeatable results from the development lab to full production when scaling up to an Admix high shear production size mixer – we back this with our process assurance warranty!

The Benchmix has a capacity for mixing 1-19 liters at up to 12,000 RPM. A new and improved touch screen interface provides the option to store over 100 presets for your formulations (set parameters such as bump value, acceleration value, and RPM). The display panel shows the amp draw, RPM and running time for current batch.

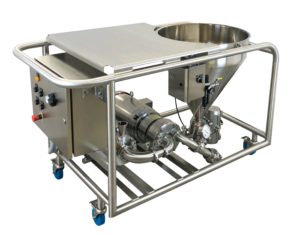

Fastfeed: The Admix Fastfeed powder induction and dispersion system consistently delivers perfect product across any batch size. This integrated, skid-mounted system enables processors to induct and disperse powders simultaneously. It inducts, wets, and disperses ingredients, instantly eliminating fisheyes.

Fastfeed: The Admix Fastfeed powder induction and dispersion system consistently delivers perfect product across any batch size. This integrated, skid-mounted system enables processors to induct and disperse powders simultaneously. It inducts, wets, and disperses ingredients, instantly eliminating fisheyes.

Learn more about the Fastfeed.

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer