The Beverage Industry

Beverage production has become more challenging with the increased popularity of sport, nutraceutical and other healthy beverages that can no longer be produced economically with conventional mixing technology.

Enter Admix. Our sanitary mixers have been utilized for decades to streamline beverage processing and we continue to innovate our products to accommodate new formulas and applications.

As the beverage industry has evolved, we’ve worked with manufacturers to produce numerous beverage types including:

Dynashear inline mixer – this system’s 3-A compliant design enables you to prevent premature plate heat exchanger burn-on, clogged strainers, and mid-day flushouts or mini-CIPs resulting from undispersed ingredients and stabilizers. Designed for 24/7 operation, it offers flow rates up to 175 GPM and seal pressure ratings up to 450 PSI at 400° F. Install the Admix Dynashear two-stage high speed disperser immediately upstream of the HTST balance tank to guarantee no agglomerates or fisheyes. Watch the new Dynashear video!

Dynashear inline mixer – this system’s 3-A compliant design enables you to prevent premature plate heat exchanger burn-on, clogged strainers, and mid-day flushouts or mini-CIPs resulting from undispersed ingredients and stabilizers. Designed for 24/7 operation, it offers flow rates up to 175 GPM and seal pressure ratings up to 450 PSI at 400° F. Install the Admix Dynashear two-stage high speed disperser immediately upstream of the HTST balance tank to guarantee no agglomerates or fisheyes. Watch the new Dynashear video!

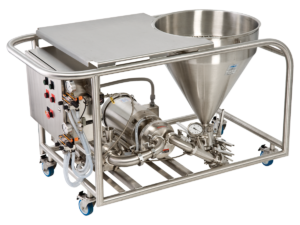

Fastfeed powder induction system – if you need 100% dispersion of proteins, gums, starches, vitamins, fiber, sweeteners, stabilizers, emulsifiers, flavors, and colors, look no further than the Fastfeed. This system instantly wets, disperses, and hydrates these popular ingredients in a single pass with no clumps or foam as it is filling your batch tank. Plus you get controlled feed rates up to 450 pounds per minute from the safety of floor level. See the latest Fastfeed video to learn how it can help your operations.

Fastfeed powder induction system – if you need 100% dispersion of proteins, gums, starches, vitamins, fiber, sweeteners, stabilizers, emulsifiers, flavors, and colors, look no further than the Fastfeed. This system instantly wets, disperses, and hydrates these popular ingredients in a single pass with no clumps or foam as it is filling your batch tank. Plus you get controlled feed rates up to 450 pounds per minute from the safety of floor level. See the latest Fastfeed video to learn how it can help your operations.

The Rotosolver high shear mixer is our flagship product with thousands of installations at food and beverage processing plants around the world.For production lines requiring 100% wetting out of powders, the Rotosolver’s patented 3-A compliant design is easy-to-clean and provides higher overall shear rates, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons.

The Rotosolver high shear mixer is our flagship product with thousands of installations at food and beverage processing plants around the world.For production lines requiring 100% wetting out of powders, the Rotosolver’s patented 3-A compliant design is easy-to-clean and provides higher overall shear rates, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons.

The Rotosolver outperforms competitors in key performance areas. For various applications, it has delivered up to:

- 50% less energy consumption

- 600% higher flow rates

- 20% higher tip speeds

- 6 times more throughput than conventional mixers

The 3-A compliant Boston Shearmill wet mill/homogenizer outperforms conventional shear pumps and colloid mills and provides very high throughputs at extreme shear rates. Inline rotor-stator machines deliver 24/7 operation; reduce solids particles with minimal dust formation; and withstand uneven flow patterns, jolts, and pressure fluctuations. And for milling of soft particles to <1 micron, or hard particles down to 1-2 microns, the shearmill produces superior particle size reduction, often in a single pass at high production rates.

The 3-A compliant Boston Shearmill wet mill/homogenizer outperforms conventional shear pumps and colloid mills and provides very high throughputs at extreme shear rates. Inline rotor-stator machines deliver 24/7 operation; reduce solids particles with minimal dust formation; and withstand uneven flow patterns, jolts, and pressure fluctuations. And for milling of soft particles to <1 micron, or hard particles down to 1-2 microns, the shearmill produces superior particle size reduction, often in a single pass at high production rates.

Admix pre-/post-sale services – whether you send a sample for free lab testing, order a trial unit for unlimited on-site testing, or need an in-plant audit or spare parts, we’re here to help. Before and after the sale, Admix has programs that allow you to test new ingredients, formulas, and applications and extend the life of your mixer in order to lower your total cost of ownership

Featured Videos

Beverage Processing Primer

The Admix Primer on Beverage Mixing & Blending offers useful information on processing beverage ingredients, production issues, and mixing technologies. We identify mixing applications and offer solutions to reduce cost while increasing efficiency and quality.

Contact us to get a free copy and see how Admix mixing expertise can improve your beverage processing!

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer