How The Admixer™ Static Mixer & Blender Works

Overview | Specifications | Options | Datasheet

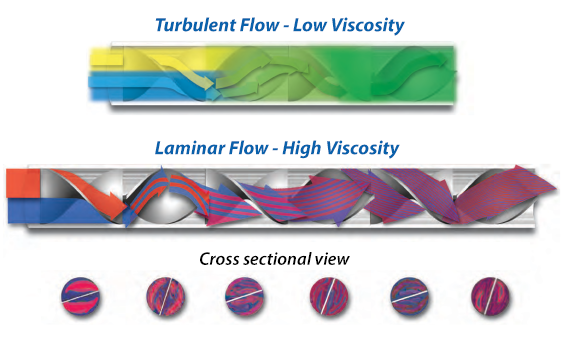

The Admixer static mixer and blender excels at processing any combination of miscible fluids. Where laminar flow exists, complete homogeneity is achieved through geometrically precise flow division regardless of viscosity, density or velocity. In turbulent flow, the Admixer utilizes radial momentum and inertia reversal to eliminate stratification of flow, temperature gradients and processed material variations.

Get a customized quote or find out about our trial program.

For difficult mixing requirements involving immiscible fluids, gas and fluids, or other 2- and 3-phase operations, the Admixer static mixer approaches ideal plug flow combined with very uniform shear. This unique combination provides predictable droplet size formation and distribution for creating fine dispersions and stable emulsions. Where heating or cooling of fluids is critical, the Admixer will increase the heat transfer rate while eliminating temperature and velocity irregularities.

For difficult mixing requirements involving immiscible fluids, gas and fluids, or other 2- and 3-phase operations, the Admixer static mixer approaches ideal plug flow combined with very uniform shear. This unique combination provides predictable droplet size formation and distribution for creating fine dispersions and stable emulsions. Where heating or cooling of fluids is critical, the Admixer will increase the heat transfer rate while eliminating temperature and velocity irregularities.

The Admixer static mixer geometry is computer-designed for optimal performance and reproducible manufacturing techniques. It will completely blend, disperse, react or heat two or more fluids in a short length of pipe. To achieve these results, the Admixer relies on the principles of radial momentum transfer, flow division and inertia reversal. These transport mechanisms eliminate concentration, velocity and thermal gradients.

While many geometric shapes have been used to create homogeneous flow, the degree of energy and mixing efficiency has been inadequately addressed. By using an elliptical or helical shape, smooth transitions are possible and no energy is wasted in back mixing. Triangular risers are used to connect the angled elliptical shapes to prevent eddy dissipation at the element edges.

When in laminar flow, two or more fluids will remain adjacent to each other indefinitely unless disrupted. The mixing elements divide the fluids and reorient by 180º, by reversing from left hand to right hand orientation, the rapid reversal at the interface enhances the mixing effect.

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer