How the Pilot Scale Mixers Work

Overview | Specifications | Options | Datasheet

Admix pilot plant mixers are used for product development, trials or small production runs for food/beverage, cosmetic, chemical or pharmaceutical products. Affixed to a sturdy and mobile floor stand, is our high shear mixer that operates at 3450 RPM, providing the ideal tip speed for most applications.

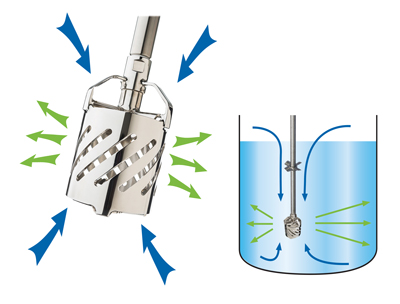

The RS-02 Piot Scale Mixer: The RS-02 comes with our flagship, patented Rotosolver® high shear mixing head. The Rotosolver is the most effective high shear impeller on the market for wetting out and dispersing powders. Its patented design is engineered to provide the optimal balance between shear and flow so that your product is completely homogenous, emulsified, and agglomerate-free in under 10 minutes. Powders, even when dumped in all at once, are immediately drawn down into the mixing head and up from the bottom, passing through multiple shear surfaces before centrifugal pressure forces material to the periphery. This combination of high shear, converging forces and continual flow means there are no dead zones in the tank and mixing is completed faster. Because of the highly efficient flow pattern created by a unique head design, minimal horsepower energy is needed to run the mixer and very little heat is generated so the temperature of your mixture remains steady. In addition, because no unmixed product is left behind, product loss concerns are a non-issue. With the Rotosolver, your ingredients will be perfectly mixed with functional ingredients intact and emulsions stable.

The RS-02 Piot Scale Mixer: The RS-02 comes with our flagship, patented Rotosolver® high shear mixing head. The Rotosolver is the most effective high shear impeller on the market for wetting out and dispersing powders. Its patented design is engineered to provide the optimal balance between shear and flow so that your product is completely homogenous, emulsified, and agglomerate-free in under 10 minutes. Powders, even when dumped in all at once, are immediately drawn down into the mixing head and up from the bottom, passing through multiple shear surfaces before centrifugal pressure forces material to the periphery. This combination of high shear, converging forces and continual flow means there are no dead zones in the tank and mixing is completed faster. Because of the highly efficient flow pattern created by a unique head design, minimal horsepower energy is needed to run the mixer and very little heat is generated so the temperature of your mixture remains steady. In addition, because no unmixed product is left behind, product loss concerns are a non-issue. With the Rotosolver, your ingredients will be perfectly mixed with functional ingredients intact and emulsions stable.

The XP-02 Pilot Scale Mixer: When reducing the particle size of certain materials such as fruit chunks, candy pieces, or nuts for example, the XP-02 is a suitable option. The XP-02 comes with our patented Rotostat® rotor-stator impeller and optional lower propeller.

The XP-02 Pilot Scale Mixer: When reducing the particle size of certain materials such as fruit chunks, candy pieces, or nuts for example, the XP-02 is a suitable option. The XP-02 comes with our patented Rotostat® rotor-stator impeller and optional lower propeller.

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer