Liquefying granulated sweeteners and bulk sugar processing

Presented by Pete Leitner, Senior VP, Sales

When it comes to adding powders into liquids and bulk sugar processing, Admix has the expertise needed to help food and beverage processors cut costs by efficiently using granulated sugar or other sweeteners like pure sucrose, fructose, or dextrose instead of procuring these sweeteners in liquid form.

When it comes to adding powders into liquids and bulk sugar processing, Admix has the expertise needed to help food and beverage processors cut costs by efficiently using granulated sugar or other sweeteners like pure sucrose, fructose, or dextrose instead of procuring these sweeteners in liquid form.

Read on to reveal factors to consider when evaluating the switch from using liquid sweetener to processing granulated sweeteners in-house. You can also download the Liquefying Granulated Sweetener PDF here.

Finding the “sweet spot” – temperature and time

Temperature and time are the two major factors to consider when batching or liquefying granulated sweeteners.

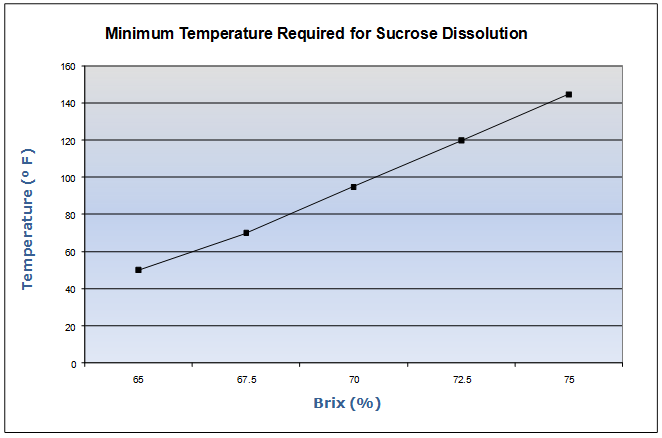

First, we consider temperature. As the percent solids of sweetener in water increases, the minimum temperature must also increase to completely dissolve the sweetener. Figure 1 shows that in order to completely dissolve 67.5 Brix sucrose, a minimum water temperature of 70°F is required. For 65 Brix, a minimum water temperature of 47°F is required. These are also the minimum temperatures required to maintain the sweetener in solution.

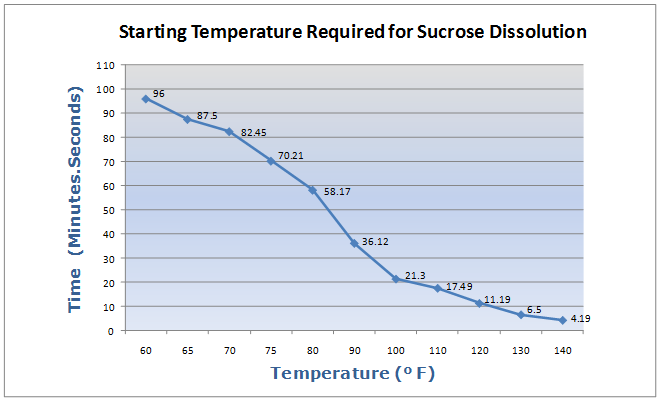

Next, we consider time. Once the desired Brix level is selected, a system must be designed to allow time for the sweetener to completely dissolve after it has been added to the liquid. Figure 2 demonstrates the time it takes for 67.5 Brix granulated sucrose to completely dissolve, and this required time cannot be reduced with higher shear levels. To achieve these levels, the crystals must be completely deagglomerated (lump-free) and a rapid particle velocity must be maintained through the liquid until it completely dissolves. Crystals that remain on the bottom of the vessel can remain for hours and may never dissolve.

Granulated vs. liquid sweeteners – purchase justification and ROI

There are several factors to consider when comparing granulated versus liquid sweeteners:

Difference in ingredient costs (comparative example)

- Processor ‘Food & Bev Ltd’ uses six tankers per week that hold 4,900 gallons of 67 Brix liquid sucrose. If cost is $3.15 per gallon delivered, total cost is $15,435 per tank

- There are 17,949 pounds of water and 36,441 pounds of sucrose in 4,900 gallons of 67 Brix liquid sucrose

- This customer’s price for granulated sucrose in 50-pound bags is $0.38 per pound delivered (purchasing in bulk bags instead of 50-pound bags will result in greater savings). Therefore 36,441 pounds of sucrose costs $13,848

- Potential ingredient savings = $1,587 per tanker ($15,435 minus $13,848) multiplied by 6 tankers per week multiplied by 50 weeks per year = $476,100

Reduction in transportation costsThe Food & Bev Ltd example considers a delivered price. Typically, transportation costs would be broken out as there may be additional savings based on proximity to the sucrose source, and also whether a facility has a rail siding (granulated can be delivered by lower cost rail; liquid sucrose generally is not).

Reduction of large capacity areas – heated bulk and reserve storageDepending on Brix level and the type of sweetener used, a minimum temperature must be used to make and store liquid sweetener. When liquid sweetener is purchased in bulk, plants typically have large capacity storage areas consisting of tanks in a “hot room” or that have hot water jackets. All this storage can be eliminated by liquefying granular sugar in a surge/storage tank that typically holds a half-day production requirement. Significant savings comes from heating and cleaning costs, and the elimination of vessels, pumps, piping, and required floor space.

Micro issuesSmall batches may reduce insect activity (airborne and crawling) around large silo storage areas. Microbiological activity may be reduced in small batching processes. Ultraviolet, over-tank sterilization apparatus may not be needed where fresh batches of liquid sucrose are constantly available.

Flavor profileA cleaner flavor profile is likely with on-demand or “fresh” batching operations.

Better temperature controlSmall batching capability may allow for more accurate temperature tolerance control that could help processing parameters downstream. Tanker delivery temperatures are not always on the money.

Control over production scheduleScheduling tankers for delivery is difficult as lead times are often up to two weeks. Estimating when reserve capacity will be available for deliveries is another challenging variable. By making liquid sweetener in-house, you are in better control your production schedule and ingredient reserves.

Sugar processing equipment from Admix

In-tank batch systems – these systems require manually dumping bags into a vessel equipped with the correct mixer. Some sweeteners are difficult to dissolve with a conventional mixer, but the 3-A compliant Rotosolver high shear mixer quickly disperses granular sugar to cut mixing time from 30 minutes to 10 minutes in cold water. This increases production capacity and reduces the number of tanks needed. For a low-shear option, the RotoMAXX II in-tank batch agitator is perfect for hold tanks and also delivers a sanitary 3-A compliant design.Factors to keep in mind when selecting this method include:Inline powder induction systems – Admix powder induction technology allows dependable introduction of granular sweeteners directly into a liquid flow stream. In a single pass, these systems are capable of creating 44 Brix. On a recirculation loop, slurries up to 80 Brix are achievable.The FastFeed inline powder induction and dispersion system not only provides robust powder induction with moderate to very high shear rates, but has operator-friendly features for improved safety and ergonomics. The Optifeed is another inline powder induction system that can handle wide viscosity and density swings.

Advantages of inline systems include:

- Rapid rates up to 450 pounds per minute of incorporation of granular sweeteners

- Easily adapts to bulk bag or silo source

- Seemless system automation

- Instant feedback is available for control and QA with an incorporated inline Brix meter on the re-circulation loop

- Heat exchangers can easily be installed into these loops

- Sweetener addition can start earlier in the cycle as no “minimum liquid depth” is required before addition of dry material begins

- Improved ergonomics and safety as ingredients are added floor level and the need to climb stairs to elevated decks is eliminated

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer