How The Boston Shearmill Wet Mill/Homogenizer Works

Overview | Specifications | Options

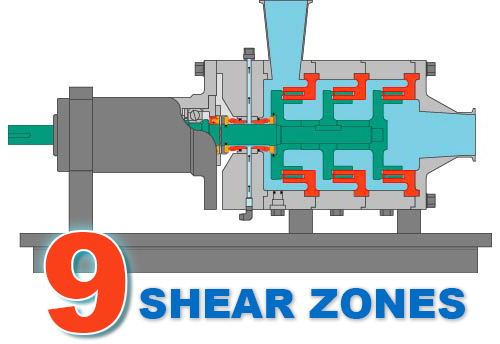

Boston Shearmills are constructed of a multi-slot rotor turning at high speeds in close proximity to a multi-port stator. Each shear head of the homogenizer consists of a rotor and stator, each with a double ring design. This results in three distinct, high intensity work zones at each rotor / stator location where the mixture passes:

- between the first set of rotor slots or teeth and the first ring of slots on the stator

- between the first ring of slots on the stator and the second ring of slots in the rotor

- between the second ring of slots in both the rotor and stator

Models with three shear heads provide nine high shear work zones to handle your toughest processing needs.

They are capable of processing very high throughputs at extreme shear rates producing an average mean droplet size of 1-3 microns.

Jesper Sæderup Lindeløv, Managing Director

Jesper Sæderup Lindeløv, Managing Director Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Knud Erik Juhl Jensen, General Manager, Admix Europe ApS

Patrick Lakin, Director of Sales and Marketing

Patrick Lakin, Director of Sales and Marketing Kara Martakos, Human Resources Director

Kara Martakos, Human Resources Director Keith Cheries, Director of Sales Operations

Keith Cheries, Director of Sales Operations Eric Therriault, Vice President of Engineering

Eric Therriault, Vice President of Engineering Bob Trottier, Vice President of Operations

Bob Trottier, Vice President of Operations Dan Cameron, Chief Financial Officer

Dan Cameron, Chief Financial Officer Mike Rizzo, Chief Executive Officer

Mike Rizzo, Chief Executive Officer